Product Information:

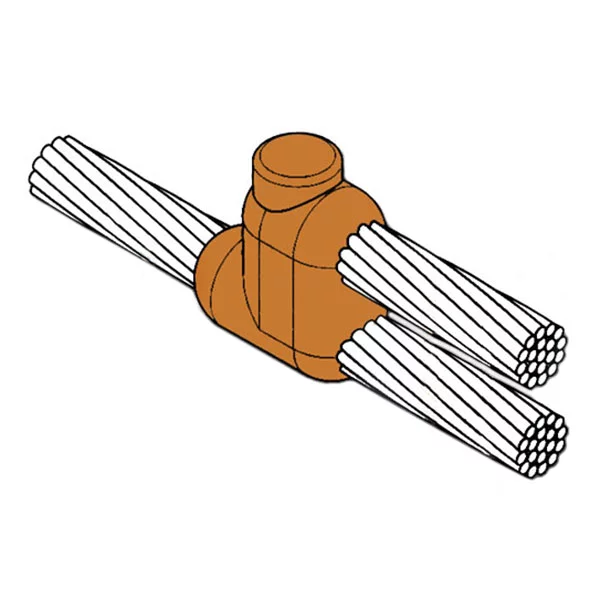

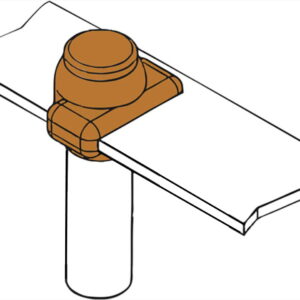

Three Way Cable Joint is a cable to cable exothermic welded connection that requires HCD Handle Clamp.

The AuraWeld Exothermic Connection is a permanent, zero-maintenance weld solution providing up to 50 years of service life. Unlike pressure-type connections – such as bolts or crimps – AuraWeld welds do not loosen or degrade with time, providing consistent electrical performance without increased resistance. The granular powder of the AuraWeld metal includes copper oxide, aluminium, and flux and is available in standard sizes.

AuraWeld Mould Features

- High-quality graphite that provides ease of machining and resilience to thermal and mechanical shocks during welding, with heat over 2000ºC.

- Designed for 50-60 weld connection